Common Lubricants Used in Chain Drives

Industrial lubricants market is expected to grow at a CAGR of 14 billion by 2022-2027. Motors convert electrical energy into mechanical energy and the resulting motion and torque drives a load.

Best Chain Lubes For Bikes Cycling Weekly

Precision roller chain covered by American National Standard ASME B291.

. Typically a mixture of compressed air and injected lubricant exits the air end and is passed to a sump where the lubricant is removed from the compressed air. 22 2022 GLOBE NEWSWIRE -- According to Ariztons latest research report the US. Dual-line lubrication systems.

The XL2E-BA casting that was introduced in 99 was used up through 2000 when the OHV engine was discontinued. Viscosity thickening is controlled and engines run cleaner promoting cooler operation. It is driven by a.

Manual lubrication tools. These costs include the costs of fuel lubricants tires equipment maintenance and repairs. Dry lubes are cleaner but need more frequent.

The most effective motor control solution is the variable frequency drive or adjustable speed drive. Can also be used in hydrostatic drives power steering systems brake systems and other applications where products of this type and specification is required. Multi-line lubrication systems.

Silent inverted-tooth chain covered by ASME B292. Electric motors are the backbone of modern automation. And engineering steel offset sidebar chain covered by ASME B2910.

It is used across food beverage processing machines such as conveyor belts pumps and mixers for blending canning cutting cooking slicing peeling brewing and bottling. O-rings are a form of gasket or seal that features a round cross-section. This was the same casting that was used in the SOHC 40L for 97 and 98 so the cranks from both engines can be interchanged in spite of the fact that Ford gave them different part numbers.

Automatic lubrication systems. They are commonly used to prevent leaks of either fluids or gases from occurring in products systems or machinery and find use across a variety of industries. Progressive lubrication systems.

Figure 31 Equipment Cost Model. The South US will continue to dominate the. Minimal quantity lubrication systems.

Oil circulation lubrication systems. A rotary-screw compressor is a type of gas compressor such as an air compressor that uses a rotary-type positive-displacement mechanismThese compressors are common in industrial applications and replace more traditional piston compressors where larger volumes of compressed gas are needed eg. Liquimatic HV 46 is particularly recommended for contractors plant and machinery.

Wall Street closes higher boosted by tech stocks gains on upbeat earnings. The three most common types of chains used for drives are. Belt tension at steady state can be calculated as66Tb137fLg2mi2mbmmcosδHgmmwhere Tb is the belt tension N f is the coefficient of friction L is the conveyer length in meter divided by two g is the acceleration due to gravity 981ms2 mi is the load of idlers within 1m length of conveyer belt kg mb is the load.

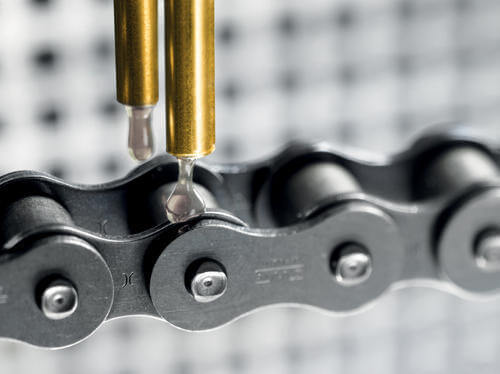

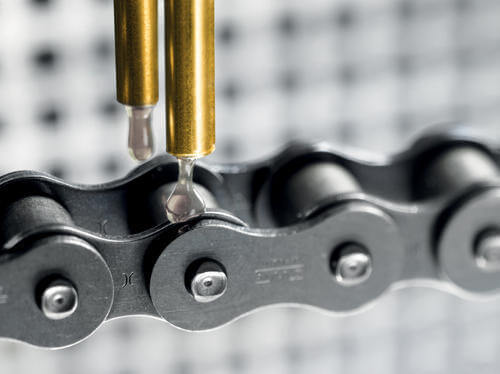

The carrier evaporates leaving a solid lubricant. As sticky liquids wet chain lubes flow into the nooks and crannies of your chain to lubricate it and flow back in when displaced by pressure while dry chain lubes use a volatile carrier to wash waxy lubricant into your chain. One type of O-ring material.

The global industrial lubricants market size was valued at 57 billion in 2021 growing at a CAGR of 363 during 2022-2027Chicago Aug. Food grade lubricants certified with NSF-H1 ensures the. Directional and speed changes are used to separate most of the liquid.

98 of products ordered ship from stock and deliver same or next day. Longer rods also mean shorter and lighter pistons can be used so the additional weight of the rods is more or less offset by the reduced weight of the pistons. Single-line lubrication systems.

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic industrial and agricultural machinery including conveyors wire- and tube-drawing machines printing presses cars motorcycles and bicyclesIt consists of a series of short cylindrical rollers held together by side links. Stocks ended higher on Wednesday with the tech-heavy Nasdaq booking a 16 gain on. Drives vary motor input frequency and voltage to control motor speed and torque.

Volatilization burn-off oxidation and excessive deposit formation from high heat are greatly reduced. Oil and air lubrication systems. This crank appears to be.

Wet chain lubes are usually better at resisting water. For large refrigeration cycles such as chillers or for. H1 lubricants are a globally recognized certification used in the food beverage industry where incidental food contact is possible.

DIN 51524 Part 3 HVLP Poclain HV 46 Sperry Vickers I-286-S3 M-2950-S. Longer rods require the wrist pin to be located higher in the piston or the engine has to have a taller deck height to accommodate longer rods. The cost of supervision may also be spread over the labor.

For lubricant injected rotary screw compressors lubricants may be a hydrocarbon composition or a synthetic product. By Echo Wang Reuters - US. Roller chains are produced in 025 through 30-inch pitch and are used for a wide variety of drives in the slow to high.

McMaster-Carr is the complete source for your plant with over 700000 products. Resists Oxidation and High-Temperature Breakdown Premium Protection Synthetic Motor Oil is formulated to overcome the thermal deficiencies common to conventional petroleum oils. Labor costs are those costs associated with employing labor including direct wages food contributions transport and social costs including payments for health and retirement.

Best Bike Chain Lubes How To Make Your Bike Faster Quieter Smoother Bikerumor

Roller Chain Lubrication Methods Ibt Industrial Solutions Ibt Industrial Solutions

101 Guide Understanding Chain Drive And The Need For Chain Lubrication

No comments for "Common Lubricants Used in Chain Drives"

Post a Comment